THIS GUIDE IS NOT ALL INCLUSIVE!

It is intended to be used as a tool for training and for quick field reference.

Refer to current training manuals and your department policies for detailed explanations.

There is no substitute for regular, quality, hands-on training by a qualified instructor.

The techniques and procedures illustrated in this guide follow NFPA standards and OSHA regulations as much as possible.

This guide can be used by rescuers at all skill levels but was specifically developed for fully qualified technical rescue technicians.

Special operations are inherently dangerous and serious injury or fatality may result from improper performance of these techniques.

The author accepts no responsibility for damage, loss, injury or death resulting from information contained in or omitted from this guide.

Thanks to the Phoenix Fire Department and everyone who helped make this guide possible.

Special thanks to my friend Ron Jamison for helping to write this guide, Kathy Darrow for editing and to George Drees, Ken Phillips and Jim Frank for great ideas and input.

This guide is dedicated to all those people who go the extra inch every day to make themselves better rescuers.

This handbook is based on the Phoenix Fire Department and Arizona State Fire Marshall┴s Office technical rescue programs.

ISBN 0-9675238-4-2

Third Edition October 2003

Illustrations and text copyright c1999-2003 Tom Pendley.

All rights reserved.

No reproduction, storage or transmission without written permission of the author.

Published by Desert Rescue Research. Photos by Tom Pendley and Glenn Speight.

Cover art, text layout and design by Glenn Speight.

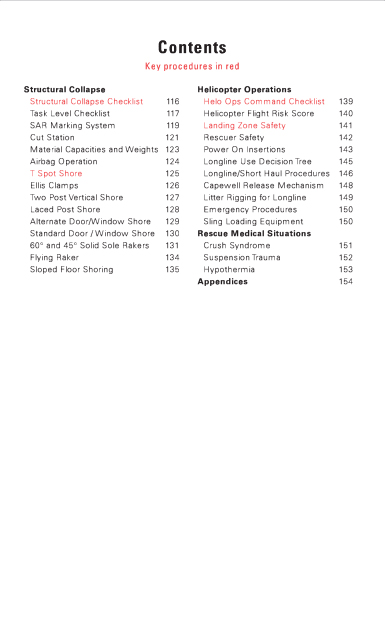

Key procedures in red

NFPA Standards 2

Risk Management 3

Incident Management 4

Time Management 6

Rope Rescue

Rope Command Checklist 7

Personal Protective Equipment 8

Terrain Types 9

Mountain Rescue Decision Tree 10

Basic Life Safety Knots 11

Load Releasing Hitch (LRH) 15

Personal Purcell Prusik System 16

Self Rescue 18

Patient Packaging 19

Low Angle Evacuation 20

Anchor Systems 21

Back-Tie Anchors 23

Directional Anchors 24

Structural Anchors 25

Fixed Belay for Edgemen 26

Edge Protection 27

Tandem Prusik Belay Setup 28

Technical Evacuation 30

Technical Evacuation Commands 33

Technical Evacuation Lower 34

Technical Evacuation Raise 35

Steep Angle Evacuation 36

High Angle Litter Rigging 37

High Angle Evacuation 38

Mechanical Advantages 39

Ganged Mechanical Advantage 41

Conversion from Lower to Raise 42

Knot Passing 43

Mid-Face Litter Scoop 46

Rescue Pick-off 48

Rescuer Based Pick-off 50

Team Based Pick-off 55

Confined Space Rescue

Con Space Command Checklist 58

Con Space Definitions 60

Con Space Entry Safety Checklist 61

Personal Protective Equipment 62

Supplied Air Station Operation 63

Remote Air Cart 64

Communication Position 65

Intercom 66

Atmospheric Monitoring 67

Ventilation 68

Extrication Device 72

Rescue Tripod and Winch 73

Winch Cable Setup 75

Rescue Tripod and Pulley System 76

Aerial Apparatus 77

Swiftwater Rescue

Swiftwater Command Checklist 79

Equipment 80

Swiftwater Rescue Comm 82

Swiftwater Hazards 83

Safe Swimming Position 84

Shore-Based Rescue: Reach 85

Shore-Based Rescue: Throw 87

Shallow Water Crossing: Wade 89

Boat Operations: Row 91

Boat on Highline 94

Strong Swimmer Rescue: Go 97

Helicopters and Swiftwater 100

Trench Rescue

Trench Command Checklist 101

Trench Incident Site Setup 103

Trench Definitions 104

Trench Hazards 105

Hydraulic Speed Shore System 106

Pneumatic Shore Placement 109

Timber Shore Step-by-Step 111

Key procedures in red

Structural Collapse

Structural Collapse Checklist 116

Task Level Checklist 117

SAR Marking System 119

Cut Station 121

Material Capacities and Weights 123

Airbag Operation 124

T Spot Shore 125

Ellis Clamps 126

Two Post Vertical Shore 127

Laced Post Shore 128

Alternate Door/Window Shore 129

Standard Door / Window Shore 130

60üőand 45üőSolid Sole Rakers 131

Flying Raker 134

Sloped Floor Shoring 135

Helicopter Operations

Helo Ops Command Checklist 139

Helicopter Flight Risk Score 140

Landing Zone Safety 141

Rescuer Safety 142

Power On Insertions 143

Longline Use Decision Tree 145

Longline/Short Haul Procedures 146

Capewell Release Mechanism 148

Litter Rigging for Longline 149

Emergency Procedures 150

Sling Loading Equipment 150

Rescue Medical Situations

Crush Syndrome 151

Suspension Trauma 152

Hypothermia 153

Appendices 154

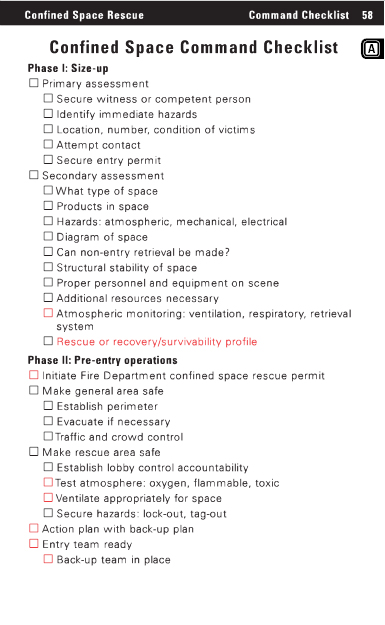

Command Checklist 58

Confined Space Command Checklist

Phase I: Size-up

Primary assessment

Secure witness or competent person

Identify immediate hazards

Location, number, condition of victims

Attempt contact

Secure entry permit

Secondary assessment

What type of space

Products in space

Hazards: atmospheric, mechanical, electrical

Diagram of space

Can non-entry retrieval be made?

Structural stability of space

Proper personnel and equipment on scene

Additional resources necessary

Atmospheric monitoring: ventilation, respiratory, retrieval system

Rescue or recovery/survivability profile

Phase II: Pre-entry operations

Initiate Fire Department confined space rescue permit

Make general area safe

Establish perimeter

Evacuate if necessary

Traffic and crowd control

Make rescue area safe

Establish lobby control accountability

Test atmosphere: oxygen, flammable, toxic

Ventilate appropriately for space

Secure hazards: lock-out, tag-out

Action plan with back-up plan

Entry team ready

Back-up team in place

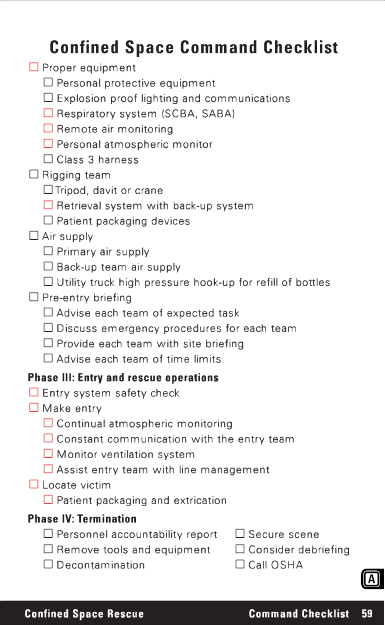

Proper equipment

Personal protective equipment

Explosion proof lighting and communications

Respiratory system (SCBA, SABA)

Remote air monitoring

Personal atmospheric monitor

Class 3 harness

Rigging team

Tripod, davit or crane

Retrieval system with back-up system

Patient packaging devices

Air supply

Primary air supply

Back-up team air supply

Utility truck high pressure hook-up for refill of bottles

Pre-entry briefing

Advise each team of expected task

Discuss emergency procedures for each team

Provide each team with site briefing

Advise each team of time limits

Phase III: Entry and rescue operations

Entry system safety check

Make entry

Continual atmospheric monitoring

Constant communication with the entry team

Monitor ventilation system

Assist entry team with line management

Locate victim

Patient packaging and extrication

Phase IV: Termination

Personnel accountability report

Secure scene

Remove tools and equipment

Consider debriefing

Decontamination

Call OSHA

Confined Space Rescue

Command Checklist 59

Definitions 60

Confined Space Rescue

OSHA 29 CFR 1910.146 applies to general industry and the rescue service.

An OSHA confined space is defined as:

1. A space large enough for personnel to physically enter.

2. Not designed for continuous employee occupancy.

3. An area with limited entry and egress.

A confined space permit is required if the space has one or more of the following hazards:

1. Atmospheric hazards.

2. Configuration hazard.

3. Engulfment hazard.

4. Any other recognized hazard.

Acceptable entry conditions

Oxygen between: 19.5% and 22.5%

Lower explosive limit (LEL): <10% of the LEL

Toxicity: < IDLH

Immediately dangerous to life and health (IDLH)

Heat stress can quickly become a life threatening hazard. Rotate crews frequently.

3 Take the extra time to carefully manage all lines.

3 Be sure to have the lobby/attendant take up all lines as the entry team returns to the outside.

3 Expect the atmosphere to suddenly become unsafe.

3 Monitor the atmosphere continuously.

TSO commands for confined space entry

Everyone take positions and prepare for entry checklist

Attendant ready? Attendant Ready

Retrieval ready? Retrieval ready

Entry team egress bottle pressures? Record pressure

Backup team egress bottle pressures? Record pressure

Personal air monitor on Monitor checks ok

Mechanical ventilation on Ventilation on

Air supply ready? Air supply ready

Entry team go on air On air

Primary comm check Primary comm OK

Secondary comm check Secondary OK

Primary light check Primary light OK

Secondary light check Secondary OK

Entry team ready? Entry team ready

Backup team ready? Backup team ready

System safety check, any problems? Solve any problems

Entry team make entry Making entry

Attendant note time of entry Time noted

Emergency checklist for backup/rescue team entry

Attendant ready? ü@Attendant ready

Retrieval ready? ü@Retrieval ready

Backup air supply ready?ü@ Air supply ready

Rescue team go on air. ü@ On air

Personal air monitor on. Monitor checks ok

Primary comm check. Primary comm OK

Secondary comm check. Secondary OK

Primary light check. Primary light OK

Secondary light check. Secondary light OK

Rescue team ready? Rescue team ready

Safety checks, any problems? Solve any problems

Rescue team make entry. Making entry

Attendant note time of entry. Time noted

Confined Space

Safety Checklist 61

Personal Protective Equipment 62

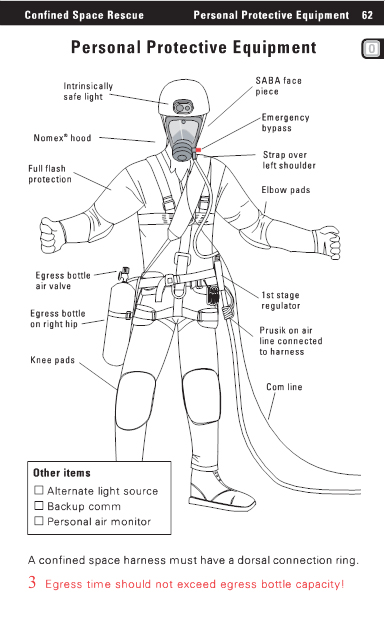

Personal Protective Equipment

Intrinsically

safe light

SABA face piece

Nomex R hood

Full flash protection

Emergency bypass

Strap over left shoulder

Elbow pads

Egress bottle air valve

Egress bottle on right hip

Knee pads

1st stage regulator

Prusik on air line connected to harness

Com line

Other items

Alternate light source

Backup comm

Personal air monitor

A confined space harness must have a dorsal connection ring.

3 Egress time should not exceed egress bottle capacity!

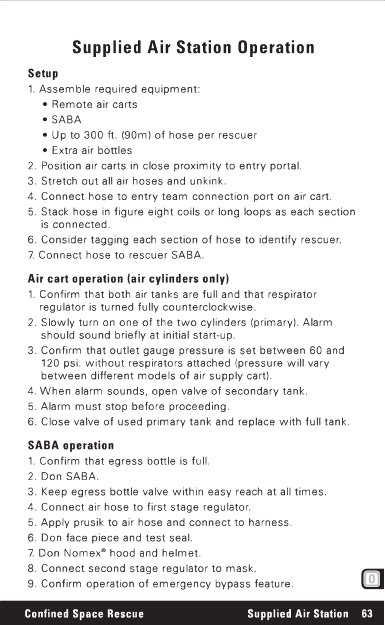

Setup

1. Assemble required equipment:

_ Remote air carts

_ SABA

_ Up to 300 ft. (90m) of hose per rescuer

_ Extra air bottles

2. Position air carts in close proximity to entry portal.

3. Stretch out all air hoses and unkink.

4. Connect hose to entry team connection port on air cart.

5. Stack hose in figure eight coils or long loops as each section is connected.

6. Consider tagging each section of hose to identify rescuer.

7. Connect hose to rescuer SABA.

Air cart operation (air cylinders only)

1. Confirm that both air tanks are full and that respirator regulator is turned fully counterclockwise.

2. Slowly turn on one of the two cylinders (primary).

Alarm should sound briefly at initial start-up.

3. Confirm that outlet gauge pressure is set between 60 and 120 psi.

without respirators attached (pressure will vary between different models of air supply cart).

4. When alarm sounds, open valve of secondary tank.

5. Alarm must stop before proceeding.

6. Close valve of used primary tank and replace with full tank.

SABA operation

1. Confirm that egress bottle is full.

2. Don SABA.

3. Keep egress bottle valve within easy reach at all times.

4. Connect air hose to first stage regulator.

5. Apply prusik to air hose and connect to harness.

6. Don face piece and test seal.

7. Don Nomex R hood and helmet.

8. Connect second stage regulator to mask.

9. Confirm operation of emergency bypass feature.

Confined Space Rescue

Supplied Air Station 63

Remote Air Supply Cart 64

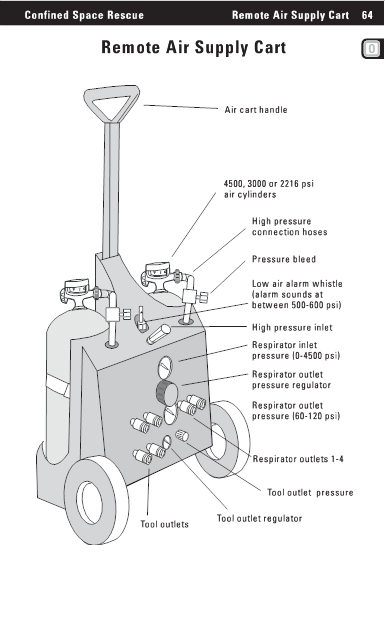

Remote Air Supply Cart

Air cart handle

4500, 3000 or 2216 psi air cylinders

High pressure connection hoses

Pressure bleed

Low air alarm whistle(alarm sounds at between 500-600 psi)

High pressure inlet

Respirator inlet pressure (0-4500 psi)

Respirator outlet pressure regulator

Respirator outlet

pressure (60-120 psi)

Respirator outlets 1-4

Tool outlet pressure

Tool outlets

Tool outlet regulator

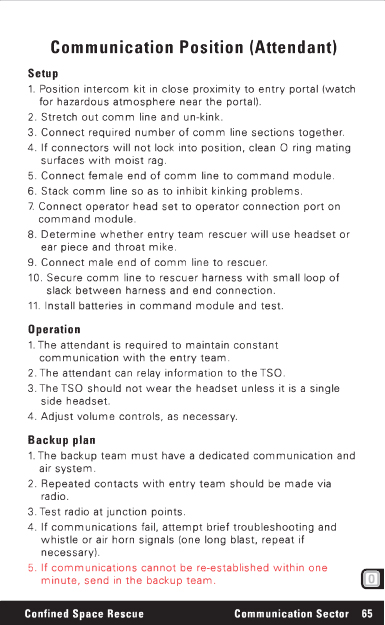

Setup

1. Position intercom kit in close proximity to entry portal (watch for hazardous atmosphere near the portal).

2. Stretch out comm line and un-kink.

3. Connect required number of comm line sections together.

4. If connectors will not lock into position, clean O ring mating surfaces with moist rag.

5. Connect female end of comm line to command module.

6. Stack comm line so as to inhibit kinking problems.

7. Connect operator head set to operator connection port on command module.

8. Determine whether entry team rescuer will use headset or ear piece and throat mike.

9. Connect male end of comm line to rescuer.

10. Secure comm line to rescuer harness with small loop of slack between harness and end connection.

11. Install batteries in command module and test.

Operation

1. The attendant is required to maintain constant communication with the entry team.

2. The attendant can relay information to the TSO.

3. The TSO should not wear the headset unless it is a single side headset.

4. Adjust volume controls, as necessary.

Backup plan

1. The backup team must have a dedicated communication and air system.

2. Repeated contacts with entry team should be made via radio.

3. Test radio at junction points.

4. If communications fail, attempt brief troubleshooting and whistle or air horn signals (one long blast, repeat if necessary).

5. If communications cannot be re-established within one minute, send in the backup team.

Confined Space Rescue

Communication Sector 65

Intercom System 66

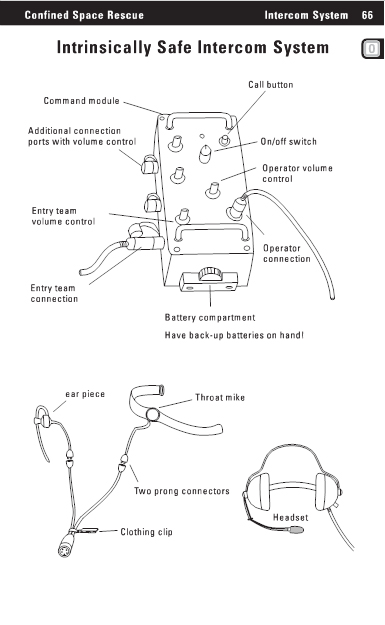

Intrinsically Safe Intercom System

Call button

Command module

Additional connection ports with volume control

On/off switch

Operator volume control

Entry team volume control

Operator connection

Entry team connection

Battery compartment

Have back-up batteries on hand!

ear piece

Throat mike

Two prong connectors

Clothing clip

Headset

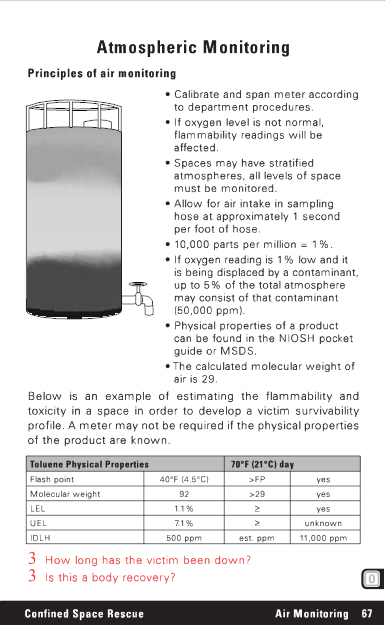

Principles of air monitoring

_ Calibrate and span meter according to department procedures.

_ If oxygen level is not normal, flammability readings will be affected.

_ Spaces may have stratified atmospheres, all levels of space must be monitored.

_ Allow for air intake in sampling hose at approximately 1 second per foot of hose.

_ 10,000 parts per million = 1%.

_ If oxygen reading is 1% low and it is being displaced by a contaminant, up to 5% of the total atmosphere may consist of that contaminant (50,000 ppm).

_ Physical properties of a product can be found in the NIOSH pocket guide or MSDS.

_ The calculated molecular weight of air is 29.

Below is an example of estimating the flammability and toxicity in a space in order to develop a victim survivability profile.

A meter may not be required if the physical properties of the product are known.

Toluene Physical Properties

70üőF (21üőC) day

Flash point

40üőF (4.5üőC) >FP yes

Molecular weight

92 >29 yes

LEL

1.1% 3 yes

UEL

7.1% 3 unknown

IDLH

500 ppm

est. ppm

11,000 ppm

3 How long has the victim been down?

3 Is this a body recovery?

Confined Space Rescue

Air Monitoring 67

Ventilation68

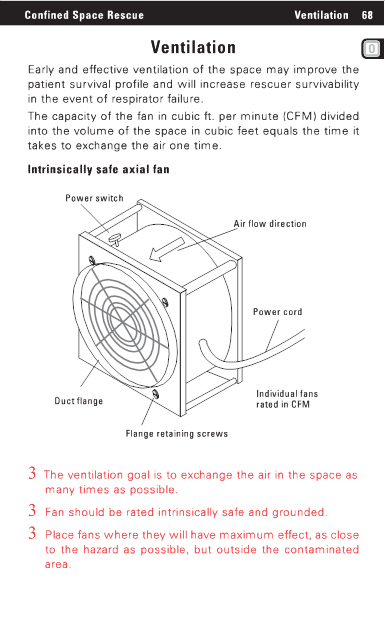

Ventilation

Early and effective ventilation of the space may improve the patient survival profile and will increase rescuer survivability in the event of respirator failure.

The capacity of the fan in cubic ft. per minute (CFM) divided into the volume of the space in cubic feet equals the time it takes to exchange the air one time.

Intrinsically safe axial fan

Power switch

Air flow direction

Power cord

Duct flange

Individual fans rated in CFM

Flange retaining screws

3 The ventilation goal is to exchange the air in the space as many times as possible.

3 Fan should be rated intrinsically safe and grounded.

3 Place fans where they will have maximum effect, as close to the hazard as possible, but outside the contaminated area.

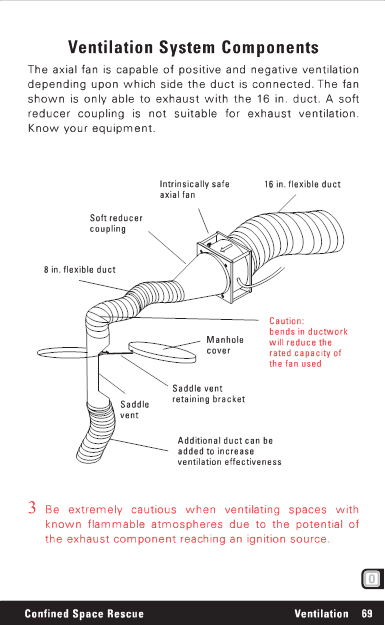

The axial fan is capable of positive and negative ventilation depending upon which side the duct is connected. The fan shown is only able to exhaust with the 16 in. duct. A soft reducer coupling is not suitable for exhaust ventilation.

Know your equipment.

Intrinsically safe axial fan

16 in. flexible duct

Soft reducer coupling

8 in. flexible duct

Manhole cover

Caution:

bends in ductwork will reduce the rated capacity of the fan used

Saddle vent

Saddle vent retaining bracket

Additional duct can be added to increase ventilation effectiveness

3 Be extremely cautious when ventilating spaces with known flammable atmospheres due to the potential of the exhaust component reaching an ignition source.

Confined Space Rescue

Ventilation 69

Ventilation 70

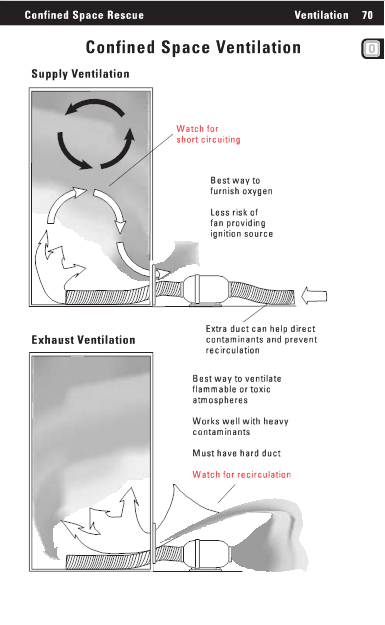

Confined Space Ventilation

Supply Ventilation

Watch for short circuiting

Best way to furnish oxygen

Less risk of fan providing ignition source

Exhaust Ventilation

Extra duct can help direct contaminants and prevent recirculation

Best way to ventilate flammable or toxic atmospheres

Works well with heavy contaminants

Must have hard duct

Watch for recirculation

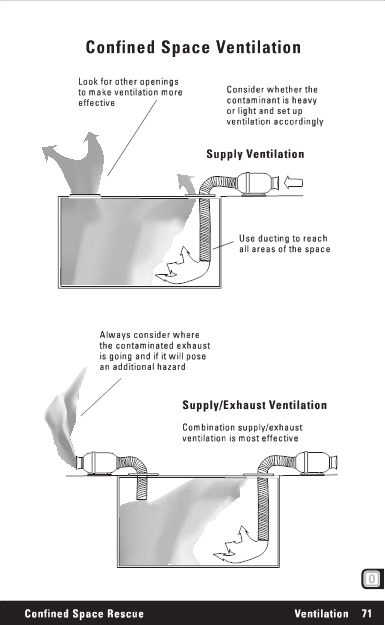

Look for other openings to make ventilation more effective

Consider whether the contaminant is heavy or light and set up ventilation accordingly

Supply Ventilation

Use ducting to reach all areas of the space

Always consider where the contaminated exhaust is going and if it will pose an additional hazard

Supply/Exhaust Ventilation

Combination supply/exhaust ventilation is most effective

Confined Space Rescue

Ventilation 71

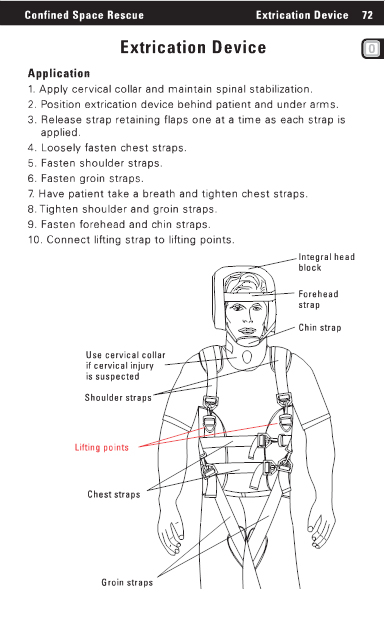

Extrication Device 72

Extrication Device

Application

1. Apply cervical collar and maintain spinal stabilization.

2. Position extrication device behind patient and under arms.

3. Release strap retaining flaps one at a time as each strap is applied.

4. Loosely fasten chest straps.

5. Fasten shoulder straps.

6. Fasten groin straps.

7. Have patient take a breath and tighten chest straps.

8. Tighten shoulder and groin straps.

9. Fasten forehead and chin straps.

10. Connect lifting strap to lifting points.

Integral head block

Forehead strap

Chin strap

Use cervical collar if cervical injury is suspected

Shoulder straps

Lifting points

Chest straps

Groin straps

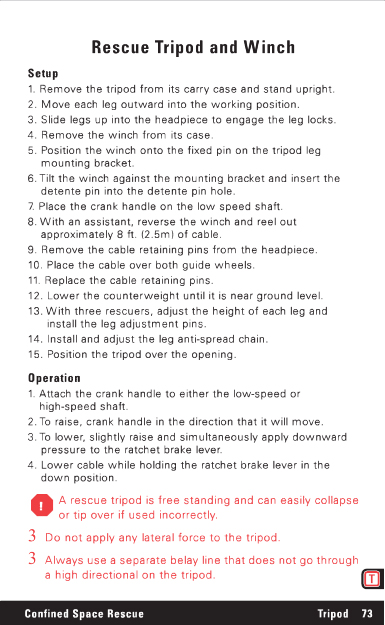

Setup

1. Remove the tripod from its carry case and stand upright.

2. Move each leg outward into the working position.

3. Slide legs up into the headpiece to engage the leg locks.

4. Remove the winch from its case.

5. Position the winch onto the fixed pin on the tripod leg mounting bracket.

6. Tilt the winch against the mounting bracket and insert the detente pin into the detente pin hole.

7. Place the crank handle on the low speed shaft.

8. With an assistant, reverse the winch and reel out approximately 8 ft. (2.5m) of cable.

9. Remove the cable retaining pins from the headpiece.

10. Place the cable over both guide wheels.

11. Replace the cable retaining pins.

12. Lower the counterweight until it is near ground level.

13. With three rescuers, adjust the height of each leg and install the leg adjustment pins.

14. Install and adjust the leg anti-spread chain.

15. Position the tripod over the opening.

Operation

1. Attach the crank handle to either the low-speed or high-speed shaft.

2. To raise, crank handle in the direction that it will move.

3. To lower, slightly raise and simultaneously apply downward pressure to the ratchet brake lever.

4. Lower cable while holding the ratchet brake lever in the down position.

A rescue tripod is free standing and can easily collapse or tip over if used incorrectly.

3 Do not apply any lateral force to the tripod.

3 Always use a separate belay line that does not go through a high directional on the tripod.

Confined Space Rescue

Tripod

73

Tripod 74

Rescue Tripod and Winch

Leg locks

350 lb. (160 kg)

load max

Eyebolt anchor point

Counterweight

Two-speed cable winch

Hook

Leg adjustment pins

Two position foot

Do not anchor CD to tripod

feetLeg anti-spread chain

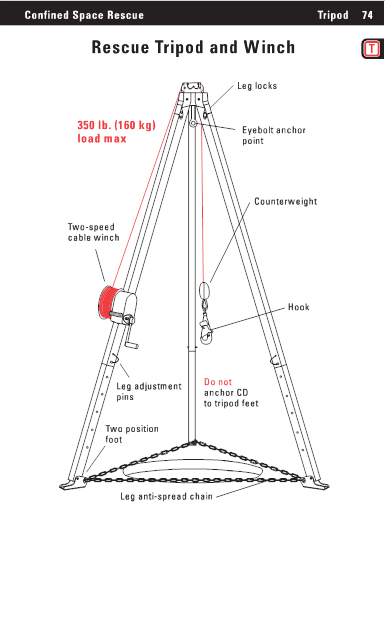

Cable retaining pins

Headpiece

Cable guide wheels

Leg locks

Eyebolt anchor point

Side View of Winch

Cable drum

Crank handle

(on low speed shaft)

High speed shaft

Detent pin

Ratchet brake lever

Confined Space Rescue

Winch 75

Tripod and Pulley System 76

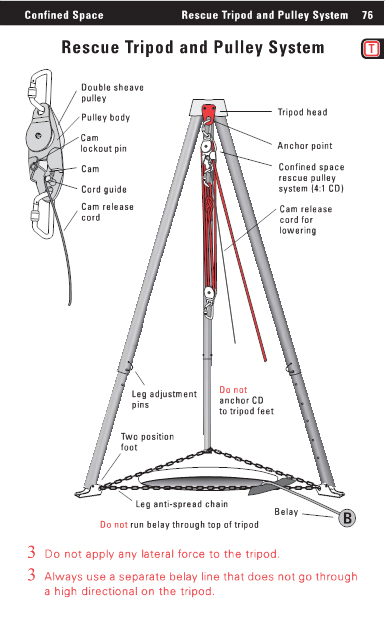

Rescue Tripod and Pulley System

Double sheave pulley

Pulley body

Cam lockout pin

Cam

Cord guide

Cam release cord

Tripod head

Anchor point

Confined space rescue pulley system (4:1 CD)

Cam release cord for lowering

Leg adjustment pins

Two position foot

Do not

anchor CD to tripod feet

Leg anti-spread chain

Belay

Do not run belay through top of tripod

3 Do not apply any lateral force to the tripod.

3 Always use a separate belay line that does not go through a high directional on the tripod.

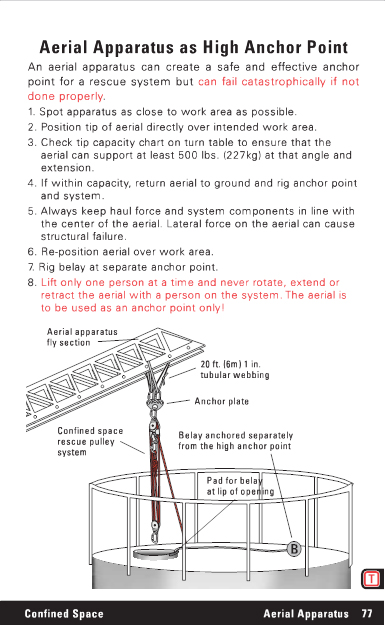

An aerial apparatus can create a safe and effective anchor point for a rescue system but can fail catastrophically if not done properly.

1. Spot apparatus as close to work area as possible.

2. Position tip of aerial directly over intended work area.

3. Check tip capacity chart on turn table to ensure that the aerial can support at least 500 lbs. (227kg) at that angle and extension.

4. If within capacity, return aerial to ground and rig anchor point and system.

5. Always keep haul force and system components in line with the center of the aerial. Lateral force on the aerial can cause structural failure.

6. Re-position aerial over work area.

7. Rig belay at separate anchor point.

8. Lift only one person at a time and never rotate, extend or retract the aerial with a person on the system. The aerial is to be used as an anchor point only!

Aerial apparatus fly section

20 ft. (6m) 1 in.

tubular webbing

Anchor plate

Confined space rescue pulley system

Belay anchored separately from the high anchor point

Pad for belay at lip of opening

Confined Space

Aerial Apparatus 77

Aerial Apparatus 78

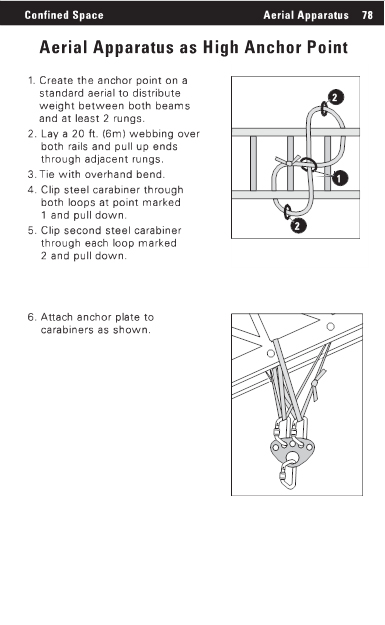

Aerial Apparatus as High Anchor Point

1. Create the anchor point on a standard aerial to distribute weight between both beams and at least 2 rungs.

2. Lay a 20 ft. (6m) webbing over both rails and pull up ends through adjacent rungs.

3. Tie with overhand bend.

4. Clip steel carabiner through both loops at point marked 1 and pull down.

5. Clip second steel carabiner through each loop marked 2 and pull down.

6. Attach anchor plate to carabiners as shown.